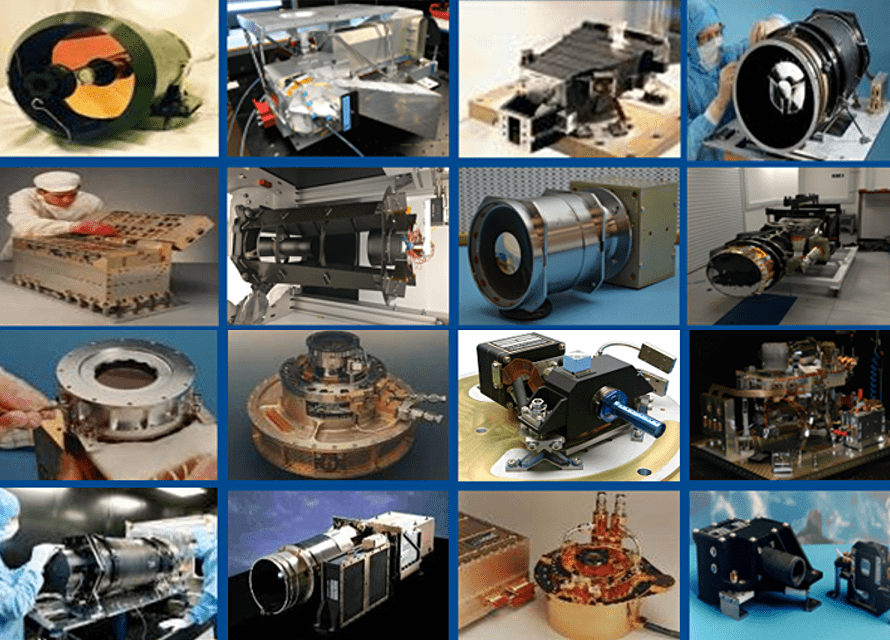

The Optical Payload group has been delivering imagers for 30+ years, to many customers from institutional flagship missions with ESA and NASA, through MOD and commercial customers.

Like many areas in SSTL it’s a multi discipline team taking optical payloads from cradle to grave.

This includes the design, assembly and verification of optical payloads through to in orbit calibration on launch and through life.

A selection of current developments...

- DarkCarb – MWIR imager 3.5m GSD

- Precision – Visible, NIR pushbroom imager <0.5m GSD

- Carbonite+ - Latest generation visible carbonite video image

- TRUTHS

- Truecolour – 9 band, 5m GSD, 120km swath imager

- Hyperspectral instruments

- Providing support to Sentinel 5 testing

Optical Systems

Working to define and develop optical payload concepts both from customer requirements and internal product innovation. Subsequently overseeing the payload development throughout its lifecycle.

This includes:

- Defining the system in terms of key optical parameters such as focal length, aperture size, MTF, SNR, spectral characteristics, line rates

- Own the system trades balancing performance against schedule, risk and cost

- Own the verification of the requirements

- Working closely with spacecraft system engineers to ensure effective overall solution

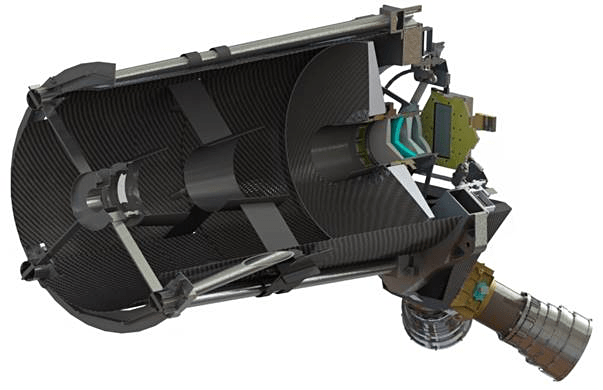

Optomechanical Design and Analysis

Working very closely with optical systems and imaging electronics the discipline is responsible for the design, analysis and testing of opto-mechanical structures.

This includes:

- Opto-mechanical system design from initial concepts to detail manufacturing drawings

- Analysis (inertial, thermal and modal) of Opto-mechanical assemblies including metering structures, mirror mounts, lens assemblies and focal plane assemblies.

- Support the integration of mechanical and optical components in the cleanroom

- Support the testing (optical, vibration and thermal) of finished assemblies.

- Support the design and testing of spacecraft as required.

Optical Design

Taking the overall optical payload concept and realising it as an optical design.

This includes:

- Optical design, tolerancing, straylight analysis

- Managing the optical design throughout the development integrating thermal and mechanical load impacts and maintaining an as built design file

- Developing the optical prescription of components and understanding manufacturers capabilities

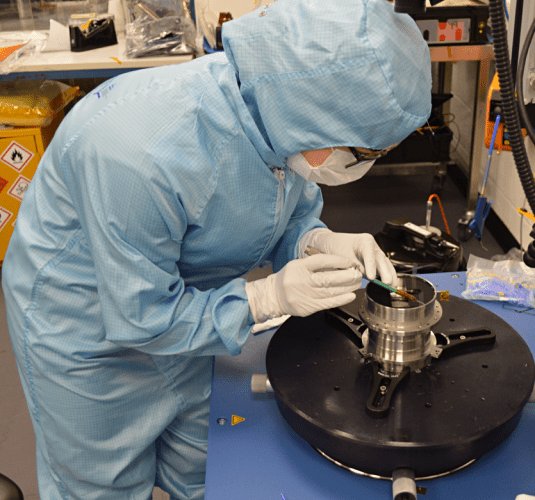

AIV

A focus on being hands-on with the build and test of the optical payload

This includes:

- Carrying out breadboard and development activities

- Developing AIV concepts, assembly flows and optical ground support requirements

- Carrying out optical payload build and test

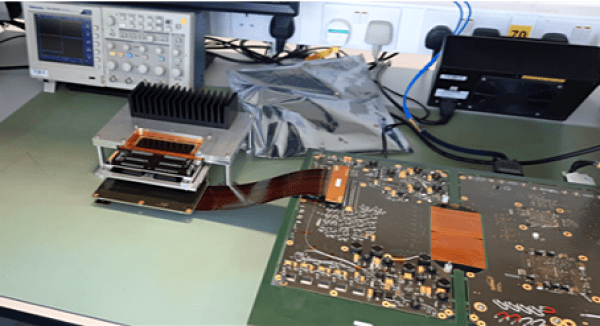

Imager Electronics

Designing and testing the electronics that are associated with the optical payload

This includes:

- Electronics for driving a range of sensors

- Service modules for power distribution, heaters, telemetry, Focus mechanisms, etc

- VHDL and software development

- Build and test of electronics modules

Image Quality/Processing

Ensuring that the final image product meets expectations, stepping beyond the requirements to understand that the final image product is fit for purpose

This includes:

- On-ground and in-orbit calibration of payloads for parameters such as MTF and radiometric calibration

- Looking at image artefacts

- Impacts of processing algorithms on final products

- Image simulation of products in development

Vacancies Within The Department

-

Imager Electronics EngineerPayloads · Guildford

-

Optical Systems Functional ManagerPayloads · Guildford · Hybrid

-

Electrical ArchitectPayloads · Guildford · Hybrid