The Spacecraft Production Department provides complete end-to-end production services from planning, to materials control, to module assembly, to spacecraft acceptance and delivering a contracted launch.

Project Manufacturing Engineers interface with internal stakeholders (including Engineering, Projects and Procurement) to manage a holistic production plan, which the Flight Assembly team then deliver.

The Assembly Integration and Test (AIT) team integrate tested modules to produce the finished spacecraft and conduct the required acceptance testing.

The Launch Manager identifies suitable launch options, down-selection & delivers the spacecraft to a contracted launch provider, ready for that all important launch deadline and count down!

We Are Responsible For

Project Manufacturing Engineers:

Managing the production plans, making sure we have the right parts available for the right place and at the right time. Providing sound manufacturing engineering advice throughout the design.

Materials Control:

Responsible for the material hardware receipt, inspection, cleaning, storage, and kitting. Despatching materials to customers and suppliers.

As Well As

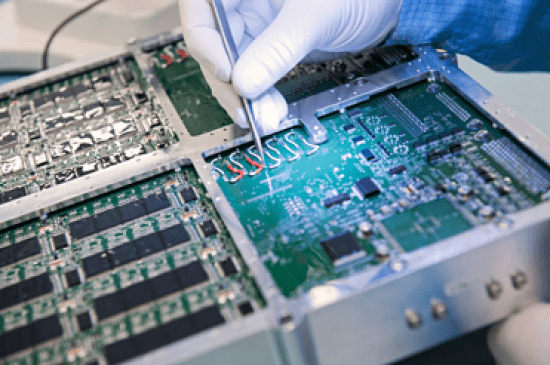

Flight Assembly and Test Lab:

Manufacturing unit-level Printed Circuit Assemblies and Solar Arrays in house ready for testing and integration onto the spacecraft.

Carrying out automated assembly and inspection, and overseeing qualification or acceptance testing in the Test Lab.

And Also

Assembly Integration and Test:

Delivering fully assembled, integrated tested spacecraft. Building spacecraft harness & Electrical Ground Support Equipment. Carrying out ambient and environmental testing that includes thermal cycling, thermal vacuum and vibration testing.

Launch Management:

Identifying & procuring suitable launches. Managing the interfaces between the satellite and the launch vehicle, including the separation system.

Already working at Surrey Satellite Technology Ltd.?

Let’s recruit together and find your next colleague.